Synthesis

There are H&X brown aluminum oxide nitridation of silicon powder, silicon dioxide and silicon tetrachloride reduction method. In large-scale industrial production, silica reduction method is more valued by the people. Reduction of silica silica powder 100 parts (by weight, hereinafter the same), mixed with 35 parts of carbon black, 100 parts of urea resin, and then 800 parts of water, 0.1 parts of aluminum oxide (as used in nuclear reactor), 1 part of oxalic acid H&X silica sand supplier parts of ammonium and nonionic surfactants (as a dispersant), for strong stirring, and aqueous ammonia was added with stirring to adjust the Ph of 9.0. Good slurry was spray-dried material, the resultant was dried in an electric furnace in a nitrogen atmosphere for 3 h at 1480 ℃ reduction nitridation reaction. Then restore the reaction product in. 720 ℃, the air carried off the carbon treatment, to obtain silicon nitride powder products.

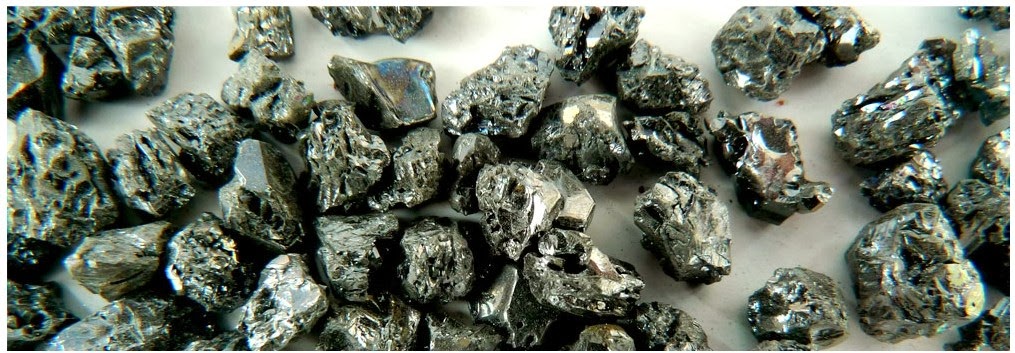

Black silicon carbide is quartz sand, petroleum coke and quality silica as the main raw material in electric arc furnace smelting. Its hardness between corundum and diamond, the mechanical strength is higher than corundum, brittle and sharp. Black silicon carbide SiC containing approximately 98.5% higher than its toughness green silicon carbide, mostly for processing low tensile strength of the material, such as glass, ceramics, stone, refractory materials, cast iron and non-ferrous metals.

2014年2月27日星期四

2014年2月25日星期二

silicon carbide powder production in a more general question

Summary: Positive silicon carbide abrasive sinister waste generated during the H&X buy silica process is the production of a more widespread problem, the extent of the problem due to the existence of the plant production conditions and the stability of the firing process varies. According to incomplete statistics, sinister waste accounted for 0.04 to 2.60 percent of total production abrasive. But domestic causes silicon carbide abrasive black H&X silicon carbide manufacturers is still lack of systematic research, while the black heart of the matter and its causes are caused by the need for discussion.

Keywords: silicon carbide abrasive waste firing process sinister production conditions roasting process binders total grains

Keywords: silicon carbide abrasive waste firing process sinister production conditions roasting process binders total grains

2014年2月20日星期四

Scope natural corundum emery

Emery Scope:, warehouses, airports, docks, parking lots, metal works, electrical H&X white fused alumina supplier, heavy machinery plants, garages, warehouse-style shopping malls and other ground.

High quality silicon carbide abrasive blasting for raw materials using modern novel and unique technology refined. RS abrasive blasting abrasive short time, high efficiency, effectiveness, and low cost characteristics. The product hardness, high toughness, good self-sharpening, sand consumption is low and can be recycled use, good finish grinding pieces; and chemical composition and stability, wear resistance, acid and alkali. The shell-shaped H&X silicon carbide suppliers abrasive, sharp corners, edges and may form a new side of the blade in constant crushing grading, making it superior to other abrasive grinding capacity. In particular, it has high hardness, specific gravity, chemical stability and its unique self-sharpening, etc. become the preferred abrasive blasting process used; while sand-blasting to clean the workpiece is an ideal material for grinding and polishing.

High quality silicon carbide abrasive blasting for raw materials using modern novel and unique technology refined. RS abrasive blasting abrasive short time, high efficiency, effectiveness, and low cost characteristics. The product hardness, high toughness, good self-sharpening, sand consumption is low and can be recycled use, good finish grinding pieces; and chemical composition and stability, wear resistance, acid and alkali. The shell-shaped H&X silicon carbide suppliers abrasive, sharp corners, edges and may form a new side of the blade in constant crushing grading, making it superior to other abrasive grinding capacity. In particular, it has high hardness, specific gravity, chemical stability and its unique self-sharpening, etc. become the preferred abrasive blasting process used; while sand-blasting to clean the workpiece is an ideal material for grinding and polishing.

2014年2月18日星期二

Silicon carbide refractories quality profile

Abstract: this paper introduces the properties of silicon carbide refractories H&X silicon carbide green, development and application of key words: silicon carbide refractories, properties, development and application of silicon carbide has high fire-resistant performance and chemical stability, so they are widely used in all kinds of refractory, but at present our country there is no complete the different content of the chemical analysis method of silicon carbide refractories. The analysis of the silicon carbide refractories quality projects generally have: free carbon, silica, silicon carbide, free silicon, ferric oxide, alumina. 1. The free carbon analysis free carbon has three methods, namely burning weight method, volumetric method, gas weight method. Burning weight method is applicable only to pure silicon carbide sample, organic and crystallization water and H&X garnet abrasive volatile nature of the refractory materials do not apply this method to determine; Gas volumetric method due to the fast analysis speed, high precision, simple operation, the most commonly used; Gas weight method because the test time is long, the accuracy is not high, not commonly used, but this method can extend the time of sample decomposition, at the same time, the carbon dioxide absorbed dose is larger, so it is suitable for the determination of silicon carbide refractories quality of high carbon refractory. 2. Analysis of silicon carbide silicon carbide has the direct method and indirect method. The indirect method is divided into determination of carbon in silicon carbide to conversion and determination of silicon in silicon carbide to conversion two kinds big. The indirect method to measure silicon low requirement to the instrument, conversion coefficient is small, but the test time is long, complex operation, not easy to master, carbon measurement method is rapid, simple, less interference, wide applicable scope, precision demand is high, but the instrument scaling factor. Commonly used gas volumetric method and weight method and infrared absorption method to measure carbon gases.

2014年2月16日星期日

Application of silicon carbide abrasive energy saving

1, the application of H&X fused silica manufacturers building materials, industrial grinding wheels using its thermal conductivity. Thermal radiation, high strength characteristics of high fever, manufacturing sheet metal kiln, kiln furniture can not only reduce capacity, but also improve the installed furnace capacity and product quality, shorten the production cycle, baked glazed ceramic sintering is ideal for indirect materials. 2, the application of energy saving aspect of the thermal stability and good thermal conductivity for heat, fuel consumption decreased by H&X quartz sand suppliers to 35% fuel savings, increased productivity by 20-30%. Especially with the discharge conveyor mining plant put inside the pipe, which is 6-7 times the normal level of abrasion wear resistant material. Silicon carbide powder is widely used in refractory, wear-resistant flooring, ceramic foam, specialty coatings, corrosion-resistant paint, flow separation and environmental protection industries.

2014年2月11日星期二

Silicon carbide abrasive universal problems exist

Keywords: binding H&X fused silica manufacturers performance silicon carbide abrasive hardness refractoriness high firing temperature oxidizing atmosphere roasting oxidation and decomposition reactions firing process

Snapshot text:

? Silicon carbide abrasive produced during calcination sinister ills Guang Sri Lanka which is the production of long universality exists any questions, problems between the extent of its existence due to the plant's production conditions and stability of the firing process varies. According to early 2073 industry survey and part of the production plant to incomplete statistics, black heart rejection rate Nom total output accounted for abrasive 0.04 to 2. H&X Aluminium hydroxide powder silicon carbide abrasive easier to produce black heart specifications.

Snapshot text:

? Silicon carbide abrasive produced during calcination sinister ills Guang Sri Lanka which is the production of long universality exists any questions, problems between the extent of its existence due to the plant's production conditions and stability of the firing process varies. According to early 2073 industry survey and part of the production plant to incomplete statistics, black heart rejection rate Nom total output accounted for abrasive 0.04 to 2. H&X Aluminium hydroxide powder silicon carbide abrasive easier to produce black heart specifications.

2014年2月10日星期一

The synthesis of silicon carbide and main purpose

By the sand and the right amount of carbon in electric furnace heating. Figure XIV - 8 Lely furnace A - graphite tube; B - adiabatic area; C - graphite rod; D - graphite heater; E - single crystal growth of crucible; F - temperature measurement with observation seam; G - temperature window silica carbide reduction method of the average particle size of 0.01 microns 1 silica powder H&X Al2O3 powder and average particle size of 0.05 mu m 2 carbon powder and the average particle size of 0.1 mu m fine crystalline under beta 0.04 a mixed type of silicon carbide powder, and then into graphite containers, in the argon gas flow (flow: 2 L/min), at 1600 ℃ for 5 h reaction, then the reaction product in air, heat for 2 h at 700 ℃, to remove residual carbon, made beta type silicon carbide powder products. The equation is as follows: SiO2 + 2 + 3 csic co starting material of silicon carbide fiber is the boiling point is 70 ℃ liquid dimethyl dichlorosilane. With the function of sodium metal. In an inert organic solvent is higher than the boiling point of sodium, sodium was scattered, molten state in which dripped with dimethyl dichlorosilane, hydrochloric acid reaction at the same time generate poly silane. Will gather silane in inert atmosphere heated to above H&X Alumina Oxide, the heat transfer reaction and polymerization reaction, generate intermediate carbon silane. The melt spinning fiber. Get of carbon silane fiber in high temperature calcination process processing, bridging reaction because the oxygen in the air, often in a nitrogen atmosphere heat treatment, the temperature is 1200 ~ 1500 ℃ was high strength of silicon carbide fibers. Figure XIV - 9 A - hydrogen gas instead should be synthetic device entry; B - hydrogen purification device; C - meter; D - constant temperature bath; E - temperature measurement using prism; F - gas exports; G - quartz glass tube; H - base material; I - high frequency induction coil;

Alumina Refractory

Bauxite (aluminous soil; bauxite), also known as alumina or bauxite, main ingredients are aluminum oxide, hydrate alumina containing impurities, is an earthy mineral. White or grey, brown yellow or light red by iron. From 4 to 3.9 g/cm3 density, hardness, H&X garnet price, opaque, very brittle. Very difficult to melt. Insoluble in water, soluble in sulfuric acid, sodium hydroxide solution. Mainly used for aluminium, refractory material.

Main ingredients

The scientific name bauxite bauxite, bauxite. Its composition is extremely complex, a variety of geological sources vary the floorboard of the hydrous alumina ore. As water soft LvShi, hard LvShi monohydrate and sanshui LvShi (Al2O3 · 3 h2o); Have a plenty of diaspore and kaolinite (2 sio2, Al2O3, 2 h2o) company; Some is given priority to with kaolinite, and with higher content of kaolinite, the form for general bauxite or kaolinite clay. Bauxite is generally formed by the chemical weathering or exogenous, there are few pure mineral, mineral always contains some impurities, more or less contain clay minerals, iron ore, titanium minerals and clastic heavy H&X silicon carbide manufacturers and so on.

Bauxite definition names is not enough unity, this is related to resources from all countries and industrial demand. Name of various periods are inconsistent, but basically the same. In China it is generally believed: "bauxite refers to the aluminum content of ore is higher (40%), al-si ratio (A/S (2.5 or higher) is greater than 2.5, which is less than the numerical value is called clay or shale or aluminum bauxite rock". In China's proven reserves of bauxite, LvShiXing monohydrate bauxite accounts for about 98% of the country's total reserves.

Main ingredients

The scientific name bauxite bauxite, bauxite. Its composition is extremely complex, a variety of geological sources vary the floorboard of the hydrous alumina ore. As water soft LvShi, hard LvShi monohydrate and sanshui LvShi (Al2O3 · 3 h2o); Have a plenty of diaspore and kaolinite (2 sio2, Al2O3, 2 h2o) company; Some is given priority to with kaolinite, and with higher content of kaolinite, the form for general bauxite or kaolinite clay. Bauxite is generally formed by the chemical weathering or exogenous, there are few pure mineral, mineral always contains some impurities, more or less contain clay minerals, iron ore, titanium minerals and clastic heavy H&X silicon carbide manufacturers and so on.

Bauxite definition names is not enough unity, this is related to resources from all countries and industrial demand. Name of various periods are inconsistent, but basically the same. In China it is generally believed: "bauxite refers to the aluminum content of ore is higher (40%), al-si ratio (A/S (2.5 or higher) is greater than 2.5, which is less than the numerical value is called clay or shale or aluminum bauxite rock". In China's proven reserves of bauxite, LvShiXing monohydrate bauxite accounts for about 98% of the country's total reserves.

订阅:

博文 (Atom)