Abstract: The current research status of white fused alumina suppliers thaumasite sulfate corrosion stone type were reviewed, raised some issues to be studied, called for the country to strengthen investigation and research in this area to explore measures to prevent THAUMASITE type of corrosion .

Keywords: thaumasite sulfate attack concrete

DOI: TU52801

Snapshot text:

Introduction

Sulfate corrosion of black silicon carbide manufacturers or mortar, there are two forms, namely ettringite type corrosion and THAUMASITE type corrosion. Ettringite type of corrosion is due to the environment of cement sulphate and calcium hydroxide reacts gypsum, plaster and these ettringite in hydrated calcium aluminate cement reacts with (C2A · 3CaSO4 · 32H2O) crystal , its volume increased more than 1.5 times the original volume.

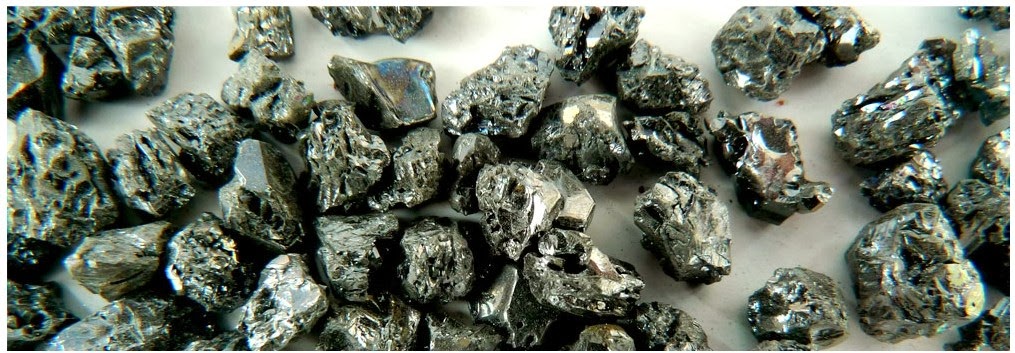

Black silicon carbide is quartz sand, petroleum coke and quality silica as the main raw material in electric arc furnace smelting. Its hardness between corundum and diamond, the mechanical strength is higher than corundum, brittle and sharp. Black silicon carbide SiC containing approximately 98.5% higher than its toughness green silicon carbide, mostly for processing low tensile strength of the material, such as glass, ceramics, stone, refractory materials, cast iron and non-ferrous metals.

2013年12月30日星期一

Detailed calcium silicon ratio and concrete

calcium silicon than the larger, more vulnerable to sulfate attack concrete and alkali-aggregate reaction. Besides ettringite recrystallization will decompose, resulting in poor stability. One of these is generally mixed with volcanic ash admixture purpose is to improve the material and silica fume silica, calcium granules than concrete, so that the mechanical properties and durability of concrete to achieve better. Theoretically hydrated calcium silicate silicon ratio is between 1.7 to 2.3 at. Over this range, the concrete will be a problem.

Quantitative analysis THAUMASITE formation mechanism

Abstract : Two experimental methods designed synthetic THAUMASITE to study erosion mechanism of cement-based silica sand manufacturers THAUMASITE 's . X-ray diffraction , Raman spectroscopy of cement -based materials instars qualitative analysis of reaction products , and using the Rietveld method for quantitative characterization. The results showed that: THAUMASITE in ettringite can still form an environment , it can be directly described reaction ; in the presence of ettringite formation environment THAUMASITE also be generated , indicating that the carbon and sulfur wollastonite formation mechanism Woodfordite transition mechanism exists. The presence of ettringite increases the yield of thaumasite . In comparison , Woodfordite transition mechanism is more likely to occur than the direct formation mechanism , and the two mechanisms can coexist simultaneously.

Keywords : quantitative Rietveld method based materials THAUMASITE cement analysis

Funds: China Building garnet manufacturers Academy , State Key Laboratory of Green Building Materials Open Fund " cement-based materials THAUMASITE quantitative characterization " ( 533001 ) funded projects

CLC : TU528

Snapshot text :

Thaumasite stone (CaCO3 CaSiO3 CaSO4 15H2O) is due to cement-based materials under long-term immersion in sulfate environment , and with adequate water sources and the environment carbonate produced [ 1 ] . THAUMASITE formation mechanism is now more recognized in two ways: one is the erosion of the environment sulfate , aggregate or carbonized get carbonates, adequate water and hardened cement paste in C-S-H react directly .

Keywords : quantitative Rietveld method based materials THAUMASITE cement analysis

Funds: China Building garnet manufacturers Academy , State Key Laboratory of Green Building Materials Open Fund " cement-based materials THAUMASITE quantitative characterization " ( 533001 ) funded projects

CLC : TU528

Snapshot text :

Thaumasite stone (CaCO3 CaSiO3 CaSO4 15H2O) is due to cement-based materials under long-term immersion in sulfate environment , and with adequate water sources and the environment carbonate produced [ 1 ] . THAUMASITE formation mechanism is now more recognized in two ways: one is the erosion of the environment sulfate , aggregate or carbonized get carbonates, adequate water and hardened cement paste in C-S-H react directly .

2013年12月29日星期日

Calcium silicon ratio to ensure the use of best quality aerated concrete

Summary : Positive since 2010 " aerated concrete production waste pulp mill technology and mix back silicon carbide price " [ 1 ] After the article was published, received many calls and letters from enthusiastic readers , and claimed that in almost identical conditions , but also that the parameters ( temperature , pressure, time , quality, etc. ) under the same circumstances, but with the same cast a tie instability phenomenon than the production of aerated concrete : the slurry in the mold box sent gas height vary greatly, sometimes hair dissatisfied , sometimes overflowing slurry , high or low quality products , fused aluminium oxide

Keywords : silicon calcium fly ash aerated concrete mix concrete production than raw computing process conditions optimal hydration products of cement lime

CLC : TU528

Snapshot text :

Since 2010 , " aerated concrete production waste pulp mill technology and mix back calculation " [ 1 ] after the article was published, received many calls and letters from enthusiastic readers , and claimed that in almost identical conditions , which is the parameters ( temperature , pressure, time , quality, etc. ) under the same circumstances, but with the same cast a tie instability phenomenon than the production of aerated concrete : the slurry in the mold box sent gas is high.

Keywords : silicon calcium fly ash aerated concrete mix concrete production than raw computing process conditions optimal hydration products of cement lime

CLC : TU528

Snapshot text :

Since 2010 , " aerated concrete production waste pulp mill technology and mix back calculation " [ 1 ] after the article was published, received many calls and letters from enthusiastic readers , and claimed that in almost identical conditions , which is the parameters ( temperature , pressure, time , quality, etc. ) under the same circumstances, but with the same cast a tie instability phenomenon than the production of aerated concrete : the slurry in the mold box sent gas is high.

Detailed calcium silicon

Tsio2 per milliliter of standard solution of sodium silicon carbide producers is equivalent to the number of milligrams of silica mg / ml

V milliliters of sodium hydroxide consumed during titration

G M sample quality

3, Determination of fly ash cao

3.1 Alumina Abrasive:

a, 50ml pipette; b, 400ml beaker; c, glass rod

3.2 Reagents:

a, 2% calcium indicator; b, triethanolamine (1:2); c, 20% KOH; d, 0.015MEDTA standard solution

V milliliters of sodium hydroxide consumed during titration

G M sample quality

3, Determination of fly ash cao

3.1 Alumina Abrasive:

a, 50ml pipette; b, 400ml beaker; c, glass rod

3.2 Reagents:

a, 2% calcium indicator; b, triethanolamine (1:2); c, 20% KOH; d, 0.015MEDTA standard solution

Calcium silicon steps

2.3.1 imbibe pipetted sample buy silica 50ml, 250ml placed in a plastic cup;

2.3.2 Add 10 ~ 15ml of nitric acid with stirring, cooling to room temperature 30 ℃;

2.3.3 potassium chloride solution was added and stirred until a little saturated potassium chloride precipitated, was added 10ml, 15% potassium fluoride solution was placed carefully stirred 20min;

2.3.4 medium speed filter paper and washed with 5% potassium chloride solution 20ml plastic cup and the precipitate was washed three times;

2.3.5 garnet manufacturers the filter paper is placed along with the original precipitate plastic beaker, add 10ml of potassium chloride - ethanol solution and 1ml of phenolphthalein indicator;

2.3.6 stirring constantly with 0.15MNaOH and not washed in acid until the solution appears red, add 200ml boiling water and use 0.15MNaOH neutralized to phenolphthalein reddish

2.3.7 Sio2 content is calculated as the percentage of

Tsio2 × V × 5

Sio2 = × 100

m × 1000

2.3.2 Add 10 ~ 15ml of nitric acid with stirring, cooling to room temperature 30 ℃;

2.3.3 potassium chloride solution was added and stirred until a little saturated potassium chloride precipitated, was added 10ml, 15% potassium fluoride solution was placed carefully stirred 20min;

2.3.4 medium speed filter paper and washed with 5% potassium chloride solution 20ml plastic cup and the precipitate was washed three times;

2.3.5 garnet manufacturers the filter paper is placed along with the original precipitate plastic beaker, add 10ml of potassium chloride - ethanol solution and 1ml of phenolphthalein indicator;

2.3.6 stirring constantly with 0.15MNaOH and not washed in acid until the solution appears red, add 200ml boiling water and use 0.15MNaOH neutralized to phenolphthalein reddish

2.3.7 Sio2 content is calculated as the percentage of

Tsio2 × V × 5

Sio2 = × 100

m × 1000

How autoclaved aerated brick-lime-silica ratio is counted out

1, the solution is equipped with:

1.1 Weigh the dried sample had 105-110 ℃, accurate to 0.001g, silver crucible is placed;

1.2 added 6-7g sodium Aluminium hydroxide;

1.3 Ma boiling furnace gradually from a low melting temperature to 650 ℃ 20min;

1.4 Remove the cooling, the crucible into the already nearly filled with 100ml of boiling water in a beaker, to be completely leached frit, remove the crucible;

1.5 with dilute hydrochloric acid and washed with hot water and the lid of the crucible, once 30ml of hydrochloric acid was added under stirring;

1.6 1ml of the nitric acid solution was added and heated to boiling, cooled, and then shifted 250ml china silicon carbide flask is diluted to the mark with water, shake up.

2, fly ash Sio2 determination:

2.1 Instrument:

a, electro-optical analysis level; b, 250ml plastic cups; c, 250mm plastic rods; d, plastic funnel;

e, 50ml pipette

2.2 Reagents:

a, 15% potassium fluoride; b, 5% potassium chloride; c, 5% potassium chloride - ethanol solution; d, phenolphthalein indicator;

e, 0.15M NaoH standard solution

1.1 Weigh the dried sample had 105-110 ℃, accurate to 0.001g, silver crucible is placed;

1.2 added 6-7g sodium Aluminium hydroxide;

1.3 Ma boiling furnace gradually from a low melting temperature to 650 ℃ 20min;

1.4 Remove the cooling, the crucible into the already nearly filled with 100ml of boiling water in a beaker, to be completely leached frit, remove the crucible;

1.5 with dilute hydrochloric acid and washed with hot water and the lid of the crucible, once 30ml of hydrochloric acid was added under stirring;

1.6 1ml of the nitric acid solution was added and heated to boiling, cooled, and then shifted 250ml china silicon carbide flask is diluted to the mark with water, shake up.

2, fly ash Sio2 determination:

2.1 Instrument:

a, electro-optical analysis level; b, 250ml plastic cups; c, 250mm plastic rods; d, plastic funnel;

e, 50ml pipette

2.2 Reagents:

a, 15% potassium fluoride; b, 5% potassium chloride; c, 5% potassium chloride - ethanol solution; d, phenolphthalein indicator;

e, 0.15M NaoH standard solution

Gypsum is also calcium silicon material

In particular, gypsum also be included in the calcium granules material.

Gypsum calcium Calculated: Laboratory Gypsum we calculated a substantially sulfur trioxide, calculate the content of CaSO4, the content of dihydrate gypsum, and the content of CaO (Ca according SO3: 40, O: 16, H: 1, S: 32).

SO3 molar mass of 32 +16 * 3 = 80g/mol; (S to 32, O to 16); CaO molar mass of 56g/mol; (Ca to 40, O to 16); CaSO4 molar mass = 56 +80 136g/mol (written CaO · SO3); CaSO4 · 2H2O: water molar mass of 18, the molar mass of blast grit 172g/mol.

Then when a single laboratory out phosphogypsum SO3 content of 30% of the time, CaO content = 30% * 56/80 = 21%, CaSO4 content of 30% +21% = 51%, the content of gypsum dihydrate = 30 % * 172/80 = 64.5%

Gypsum calcium Calculated: Laboratory Gypsum we calculated a substantially sulfur trioxide, calculate the content of CaSO4, the content of dihydrate gypsum, and the content of CaO (Ca according SO3: 40, O: 16, H: 1, S: 32).

SO3 molar mass of 32 +16 * 3 = 80g/mol; (S to 32, O to 16); CaO molar mass of 56g/mol; (Ca to 40, O to 16); CaSO4 molar mass = 56 +80 136g/mol (written CaO · SO3); CaSO4 · 2H2O: water molar mass of 18, the molar mass of blast grit 172g/mol.

Then when a single laboratory out phosphogypsum SO3 content of 30% of the time, CaO content = 30% * 56/80 = 21%, CaSO4 content of 30% +21% = 51%, the content of gypsum dihydrate = 30 % * 172/80 = 64.5%

Calcium silicon ratio calculation

Production process parameters are:

Pouring calcium metal granules 43 ℃, mold is 4.20m × 1.20m × 0.6m, surface Baotou 5% water feed ratio was 0.62. Determined by trial production with the ratio of:

m (cement): m (lime): m (fly ash): m (gypsum) = 8:24:65:3;

3, calcium silicon ratio calculation method:

C / S = ((8 × 59.37% +24 × 71.5% +65 × 2.6% +3 × 30%) / 56) / ((8 × 22.7% +24 × 5.5% +65 × 46.2%) / 60) = 0.76

56 and 60, respectively, calcium oxide, silicon dioxide molar mass [1]

4, the production of aerated concrete optimal calcium silicon ratio range:

① cement - lime - fly ash aerated concrete series of 0.75 to 0.80

② cement - lime - sand aerated concrete range from 0.64 to 0.68;

③ cement - lime - metal tailings aerated concrete series of 0.55 to 0.62.

5, in the actual production of aerated concrete, when the mixing ratio of calcium silicon ratio is less than optimal calcium silicon ratio, with the strength of the products (cement, lime) to increase the amount of binder increased. When the mixing ratio of calcium silicon ratio greater than optimal calcium silicon, continue to increase the amount of binder strength products are no longer rising even decline.

Pouring calcium metal granules 43 ℃, mold is 4.20m × 1.20m × 0.6m, surface Baotou 5% water feed ratio was 0.62. Determined by trial production with the ratio of:

m (cement): m (lime): m (fly ash): m (gypsum) = 8:24:65:3;

3, calcium silicon ratio calculation method:

C / S = ((8 × 59.37% +24 × 71.5% +65 × 2.6% +3 × 30%) / 56) / ((8 × 22.7% +24 × 5.5% +65 × 46.2%) / 60) = 0.76

56 and 60, respectively, calcium oxide, silicon dioxide molar mass [1]

4, the production of aerated concrete optimal calcium silicon ratio range:

① cement - lime - fly ash aerated concrete series of 0.75 to 0.80

② cement - lime - sand aerated concrete range from 0.64 to 0.68;

③ cement - lime - metal tailings aerated concrete series of 0.55 to 0.62.

5, in the actual production of aerated concrete, when the mixing ratio of calcium silicon ratio is less than optimal calcium silicon ratio, with the strength of the products (cement, lime) to increase the amount of binder increased. When the mixing ratio of calcium silicon ratio greater than optimal calcium silicon, continue to increase the amount of binder strength products are no longer rising even decline.

2013年12月20日星期五

What people should calcium?

Carborundum Abrasives, for many people think that only children and rickets patients only need. In fact, this view is not comprehensive. Clinically there are many patients, they need calcium.

Typical symptoms of diabetes in people with diabetes is "a little", ie polydipsia, polyphagia, polyuria and weight loss due to osmotic diuresis, increased excretion of calcium in vivo, thus leading to the occurrence of diabetes, bone disease, there bone thinning, osteoporosis and even pelvic deformity or pathologic fracture.

Senile osteoporosis through middle age, endocrine dysfunction, too little activity, inadequate calcium intake and other factors, bone metabolism disorders, osteogenesis reduce excessive loss of calcium, osteoporosis, bone degeneration, performance of leg pain, pathological fractures and even hunched phenomenon.

Some pregnant women pregnant leg pain, leg cramps. Because fetal growth and development, the demand for calcium metal granules increases lead to calcium deficiency in pregnant women. In addition, low birth weight children, premature children, malnourished children, children with chronic diarrhea, should pay attention to calcium. Due to calcium deficiency in children will not only affect growth and development, but also due to calcium deficiency secondary to a variety of diseases.

Epilepsy patients in recent years, scientific research shows that long-term use of anti-epileptic drugs, the body in varying degrees of low bone mineral density and bone metabolism. Once calcium is often difficult to control epilepsy and therefore require long-term use.

"Three drink" by long-term heavy drinking or regular tea, coffee should pay attention to calcium. Bone metabolism disorders due to alcohol consumption occurs, it can lead to osteoporosis, long-term drinking coffee, due to the diuretic effect, so that calcium excretion, easily lead to calcium deficiency in vivo.

Hypoparathyroidism "A side" dysfunction or lack of, can lead to reduction in intestinal calcium absorption, causing lower serum calcium. Patient developed numbness, tingling, stiffness, spasms and a series of symptoms.

Typical symptoms of diabetes in people with diabetes is "a little", ie polydipsia, polyphagia, polyuria and weight loss due to osmotic diuresis, increased excretion of calcium in vivo, thus leading to the occurrence of diabetes, bone disease, there bone thinning, osteoporosis and even pelvic deformity or pathologic fracture.

Senile osteoporosis through middle age, endocrine dysfunction, too little activity, inadequate calcium intake and other factors, bone metabolism disorders, osteogenesis reduce excessive loss of calcium, osteoporosis, bone degeneration, performance of leg pain, pathological fractures and even hunched phenomenon.

Some pregnant women pregnant leg pain, leg cramps. Because fetal growth and development, the demand for calcium metal granules increases lead to calcium deficiency in pregnant women. In addition, low birth weight children, premature children, malnourished children, children with chronic diarrhea, should pay attention to calcium. Due to calcium deficiency in children will not only affect growth and development, but also due to calcium deficiency secondary to a variety of diseases.

Epilepsy patients in recent years, scientific research shows that long-term use of anti-epileptic drugs, the body in varying degrees of low bone mineral density and bone metabolism. Once calcium is often difficult to control epilepsy and therefore require long-term use.

"Three drink" by long-term heavy drinking or regular tea, coffee should pay attention to calcium. Bone metabolism disorders due to alcohol consumption occurs, it can lead to osteoporosis, long-term drinking coffee, due to the diuretic effect, so that calcium excretion, easily lead to calcium deficiency in vivo.

Hypoparathyroidism "A side" dysfunction or lack of, can lead to reduction in intestinal calcium absorption, causing lower serum calcium. Patient developed numbness, tingling, stiffness, spasms and a series of symptoms.

Precautions when calcium

If improper food ingredients calcium silicon, while containing excessive intake of phytic acid, oxalic acid, tannic acid foods (such as spinach, etc.) and with fatty foods (mainly lard and fat), and calcium will combine and reduce the absorption of calcium. In addition, some high-quality protein (such as beef, fish, seafood, lean pork, etc.), released in the intestine during digestion of amino acids, can reduce intestinal acidity and calcium easily absorbed form of calcium, can also reduce calcium absorption. So calcium addition, to avoid interactions and the impact of food ingredients to reduce the loss of calcium.

There are a variety of hormones hormones can promote intestinal absorption of calcium, the most important is the active vitamin D3. Low levels of active vitamin D3 elderly, affecting calcium absorption and utilization. While calcium white fused alumina suppliers need active vitamin D3. Other hormones promote intestinal calcium absorption are: estrogen, androgens, growth hormone, calcitonin. Postmenopausal women, estrogen decreases intestinal calcium absorption decreases estrogen supplementation can increase intestinal calcium absorption, increase bone mass. Estrogen replacement therapy, should begin as soon as possible after menopause, adhere to at least 75 years of age. Other hormones may also be appropriate to add to increase the calcium effect. Of course, we must supplement the hormone under the guidance of experienced doctors.

Reduce outdoor sports activities too little can lead to osteoporosis or accelerated osteoporosis. If you insist on outdoor sports, receive sunlight a day, and even refused to accept the active vitamin D3. In China, the southerners than the northerners bone content, which is due south over the northern sunlight received sufficient reason.

There are a variety of hormones hormones can promote intestinal absorption of calcium, the most important is the active vitamin D3. Low levels of active vitamin D3 elderly, affecting calcium absorption and utilization. While calcium white fused alumina suppliers need active vitamin D3. Other hormones promote intestinal calcium absorption are: estrogen, androgens, growth hormone, calcitonin. Postmenopausal women, estrogen decreases intestinal calcium absorption decreases estrogen supplementation can increase intestinal calcium absorption, increase bone mass. Estrogen replacement therapy, should begin as soon as possible after menopause, adhere to at least 75 years of age. Other hormones may also be appropriate to add to increase the calcium effect. Of course, we must supplement the hormone under the guidance of experienced doctors.

Reduce outdoor sports activities too little can lead to osteoporosis or accelerated osteoporosis. If you insist on outdoor sports, receive sunlight a day, and even refused to accept the active vitamin D3. In China, the southerners than the northerners bone content, which is due south over the northern sunlight received sufficient reason.

2013年12月19日星期四

Why still calcium calcium years

Of course, you can also help prevent salt reduction , treatment of hypertension and reduce the risk of heart attack and cerebrovascular disease , while making your weight has dropped, to sandblasting abrasive weight loss fitness purposes.

Why still calcium calcium for many years ?

In the calcium therapy, often encounter a universal problem that some people even served a few years or calcium calcium , bone mineral density at the time of inspection or the doctor says osteoporosis. Why is this ? On this issue to understand from the following aspects.

Most scholars small dose of calcium recommended to prevent osteoporosis calcium intake to 1000-1500 mg daily . At present, China produces calcium preparations , most marked in accordance with the amount of calcium dose , while the amount of calcium and calcium content vary greatly. Such as calcium lactate calcium per 8 grams only 1 gram. Dose of calcium , the calcium content must be how to fill . For example, commonly used Gaitianli and vitality calcium granules, calcium content is 25 milligrams , that such dietary calcium supplementation of 600 mg per day , then at least be served daily calcium and vitality Gaitianli 24 ( 600 mg ) , to meet the needs of the elderly and in patients with osteoporosis . Other calcium supplement is the same principle , is to be marked according to the manufacturer 's calcium content , rather than the amount of calcium , usually 600 mg daily . If the dose is too small , of course, can not receive calcium effect.

Calcium imbalance in the normal case , the ratio of phosphorus and calcium in bone is 0.6 , i.e., every 3 mEq / l of calcium have 2 mEq / l phosphorus. Calcium to phosphorus ratio is inappropriate, it will affect calcium absorption and utilization. Especially phosphorus deficiency will lead to bone loss . Elderly due to reduced intake , combined with fish , liver, meat , eggs and other foods rich in phosphorus fear , inadequate intake, despite adequate calcium supplements , but because there is not enough phosphorus , no significant increase in calcium deposition . The reason for the fresh milk osteoporosis favorable milk calcium to phosphorus ratio is appropriate to achieve calcium, phosphorus double- up role.

Why still calcium calcium for many years ?

In the calcium therapy, often encounter a universal problem that some people even served a few years or calcium calcium , bone mineral density at the time of inspection or the doctor says osteoporosis. Why is this ? On this issue to understand from the following aspects.

Most scholars small dose of calcium recommended to prevent osteoporosis calcium intake to 1000-1500 mg daily . At present, China produces calcium preparations , most marked in accordance with the amount of calcium dose , while the amount of calcium and calcium content vary greatly. Such as calcium lactate calcium per 8 grams only 1 gram. Dose of calcium , the calcium content must be how to fill . For example, commonly used Gaitianli and vitality calcium granules, calcium content is 25 milligrams , that such dietary calcium supplementation of 600 mg per day , then at least be served daily calcium and vitality Gaitianli 24 ( 600 mg ) , to meet the needs of the elderly and in patients with osteoporosis . Other calcium supplement is the same principle , is to be marked according to the manufacturer 's calcium content , rather than the amount of calcium , usually 600 mg daily . If the dose is too small , of course, can not receive calcium effect.

Calcium imbalance in the normal case , the ratio of phosphorus and calcium in bone is 0.6 , i.e., every 3 mEq / l of calcium have 2 mEq / l phosphorus. Calcium to phosphorus ratio is inappropriate, it will affect calcium absorption and utilization. Especially phosphorus deficiency will lead to bone loss . Elderly due to reduced intake , combined with fish , liver, meat , eggs and other foods rich in phosphorus fear , inadequate intake, despite adequate calcium supplements , but because there is not enough phosphorus , no significant increase in calcium deposition . The reason for the fresh milk osteoporosis favorable milk calcium to phosphorus ratio is appropriate to achieve calcium, phosphorus double- up role.

Eat less salt calcium method

For all those who are applicable. For example : the rapid growth of the girls, and more salt , calcium excretion increased, reducing absorption can lead to bone demineralization , bone dysplasia . Incidence of women , osteoporosis in post -menopausal Another example is already very high, if more salt , not only silicon carbide grit the amount of calcium , the loss of calcium also increases will accelerate its osteoporosis . In one study , the daily salt intake in postmenopausal women reduced to 4.4 grams of 10.6 grams , calcium excretion and serum calcium concentrations are greatly reduced. If you continue to re- hypertensive patients is a high -salt diet , their urinary calcium excretion than people with normal blood pressure is much higher , leading to potentially dangerous bone demineralization is also larger than normal blood pressure . Instead, eat less salt , but they can reduce urinary calcium , bone density increased.

According to WHO recommended standards, the daily amount of salt to five grams is appropriate, not to exceed 6 grams. We know that people 24 hours of discharge is 3-5 grams of salt , then the food garnet suppliers 5 grams of salt per day , it lost considerable numbers and supplements to meet the normal needs. The daily amount of salt should be limited to less than 5 grams , is not easy. This need to change our eating habits for the job . Because in our country, especially in the northern residents , the amount of salt in general ones, and more than 12 grams per day , in some places , up to 20-30 grams . People should eat salty traditional habit , all of a sudden change over, is quite difficult. But people know eat less salt can be calcium , calcium can also be no cost truth , we have gradually , appropriate to reduce the amount of salt in their daily lives , I think it can be done.

In other places , there are potassium , magnesium and sodium salts of the market, the amount of sodium salt of only 65% of such ordinary salt . If you eat this salt , the salt itself has been reduced to 1/ 3 of the . Chinese autumn stone , the main ingredient is potassium chloride, bought it fine, mix with half the salt , can also play a role in reducing salt 1/2 .

According to WHO recommended standards, the daily amount of salt to five grams is appropriate, not to exceed 6 grams. We know that people 24 hours of discharge is 3-5 grams of salt , then the food garnet suppliers 5 grams of salt per day , it lost considerable numbers and supplements to meet the normal needs. The daily amount of salt should be limited to less than 5 grams , is not easy. This need to change our eating habits for the job . Because in our country, especially in the northern residents , the amount of salt in general ones, and more than 12 grams per day , in some places , up to 20-30 grams . People should eat salty traditional habit , all of a sudden change over, is quite difficult. But people know eat less salt can be calcium , calcium can also be no cost truth , we have gradually , appropriate to reduce the amount of salt in their daily lives , I think it can be done.

In other places , there are potassium , magnesium and sodium salts of the market, the amount of sodium salt of only 65% of such ordinary salt . If you eat this salt , the salt itself has been reduced to 1/ 3 of the . Chinese autumn stone , the main ingredient is potassium chloride, bought it fine, mix with half the salt , can also play a role in reducing salt 1/2 .

Daily food , calcium silicon

Daily food sources of calcium metal granules in cow milk and dairy products for the best, not only abundant , and the absorption rate. Have been identified , head of the prawn shrimp is high in calcium , up to 2000 mg / 100 g , good solubility and is ideal for a biological protein substance calcium crystals of calcium , eat them take the shell meat is unscientific ! Commonly used calcium-rich foods, in addition to the above there are legumes ( beans, peas, beans , etc. and their products ) , walnuts, sesame seeds , seaweed, kelp , etc.

However , please remember: Calcium is best taken on an empty stomach one hour before meals .

(2) calcium shortcuts - eat less salt

I remember this case on the ancient art of war : win the battle , not the best solution ; win without fighting , the best policy . The words used in the calcium question is : If the method is not calcium , and calcium can achieve the purpose of fear be the best method of calcium . So , there is no calcium and calcium ways to achieve it? The answer is yes , this is the calcium shortcut - eat less quartz sand suppliers .

Eat less salt calcium method , first proposed by British scientists . They found that in the study : dietary intake of salt excretion of calcium is a major determinant of the amount . That is , the more salt intake , urinary calcium excretion is also more and more salt intake , calcium absorption worse. Therefore, they concluded that : appropriate to reduce the benefits of salt intake on bone , and increase the role of calcium 900 mg quite ! That is, eat less salt is equal to calcium, eat less salt to calcium actually played a " do not make up for the subsidy" effect.

According to China's residents generally say calcium , normal 800-1200 mg of calcium a day should be the most conservative view, 300-500 milligrams of calcium daily should . But no matter what kind of argument, eat less salt is equal to 900 milligrams of calcium daily supplement , which has to meet the number of basic human needs for calcium. Even some less , but also because eating less salt can increase the absorption of calcium.

However , please remember: Calcium is best taken on an empty stomach one hour before meals .

(2) calcium shortcuts - eat less salt

I remember this case on the ancient art of war : win the battle , not the best solution ; win without fighting , the best policy . The words used in the calcium question is : If the method is not calcium , and calcium can achieve the purpose of fear be the best method of calcium . So , there is no calcium and calcium ways to achieve it? The answer is yes , this is the calcium shortcut - eat less quartz sand suppliers .

Eat less salt calcium method , first proposed by British scientists . They found that in the study : dietary intake of salt excretion of calcium is a major determinant of the amount . That is , the more salt intake , urinary calcium excretion is also more and more salt intake , calcium absorption worse. Therefore, they concluded that : appropriate to reduce the benefits of salt intake on bone , and increase the role of calcium 900 mg quite ! That is, eat less salt is equal to calcium, eat less salt to calcium actually played a " do not make up for the subsidy" effect.

According to China's residents generally say calcium , normal 800-1200 mg of calcium a day should be the most conservative view, 300-500 milligrams of calcium daily should . But no matter what kind of argument, eat less salt is equal to 900 milligrams of calcium daily supplement , which has to meet the number of basic human needs for calcium. Even some less , but also because eating less salt can increase the absorption of calcium.

The role of calcium silicon

Why do we eat every day Brown Corundum foods , such as beans, dairy products, fish , crustaceans , bone , etc., but also the body of calcium it . Originally, calcium -containing foods , mostly dissolved calcium is not easily absorbed . But also because with the cereal , dishes with meal , meat, grains contain phytic acid or containing acid, the calcium will become insoluble calcium can not be absorbed. Calculated according to modern nutritional standards are: the need of adult calcium ( referred to as " ionized calcium " ) of the biological dose , not less than 800 mg , children should not be less than 1000 mg. Unfortunately, for a long time , the medical community as a pure calcium calcium incorrectly ( ie, ionized calcium ) calculated that in the past could not have played many medicinal calcium real calcium effect. Fortunately, in recent years has found that this fallacy , and correct . One molecule of calcium , a calcium ion , only one word , leading to a worldwide human "calcium revolution" !

calcium granules have calcium, everyone should raise awareness of calcium , the question is what kind of calcium supplement , how to make ? Despite a long time, the medical community recognized calcium is a problem, but the three conditions ideal calcium should have , namely ① both contain high quantities , but also contains high quality pure calcium ; ② can be fully dissolved ; easily absorbed after taking ③ use . Has developed a lot , more in line with scientific requirements , the new safe and efficient calcium nutrition enhancer .

calcium granules have calcium, everyone should raise awareness of calcium , the question is what kind of calcium supplement , how to make ? Despite a long time, the medical community recognized calcium is a problem, but the three conditions ideal calcium should have , namely ① both contain high quantities , but also contains high quality pure calcium ; ② can be fully dissolved ; easily absorbed after taking ③ use . Has developed a lot , more in line with scientific requirements , the new safe and efficient calcium nutrition enhancer .

How trace elements such as silicon, calcium supplement

Investigation of many experts in the world that: Calcium deficiency is a serious threat to human disease , the global population suffer from mental and millions of great physical suffering , directly affects the improvement of human quality. Experts called on all sectors of society should be highly valued !

Fetus from maternal calcium obtained , used to make 99% of the bone , leaving only 1% in the form of free calcium ions in the blood is called " serum calcium silicon ." However, data shows that: after the birth , everyone into the different levels of calcium deficiency situation. People of any age are calcium , children and the elderly are more serious. Scientists found that since the age of 20 , the total weight of the bones to an annual rate of 1% decline, after the age of 50 , bone weight has been reduced by 30% overall - this is a scientific and startling conclusion .

As the " calcium hunger" , leading to the body's so-called "calcium move ." That is, the calcium bones constantly escape into the blood to maintain normal levels of serum calcium. The proportion between serum Carborundum Abrasives with calcium must maintain a long-term balance , otherwise , it will produce "calcium move " so abnormal calcium metabolism imbalance. A person within a few days or a month or calcium hunger temporarily affect serum calcium , but if things go on, calcium deficiency disease occurs : the child showed sparse hair , anorexia, irritability, night terrors , rickets , etc. ; youth skeletal dysplasia , eye disorders ; pregnant waist, leg pain , and affect fetal development , even teratogenic etc. ; osteoporosis in the elderly , degenerative bone hyperplasia , stone disease , hypertension , diabetes, dementia and so on.

Obviously, calcium plays an important role in the life course .

Fetus from maternal calcium obtained , used to make 99% of the bone , leaving only 1% in the form of free calcium ions in the blood is called " serum calcium silicon ." However, data shows that: after the birth , everyone into the different levels of calcium deficiency situation. People of any age are calcium , children and the elderly are more serious. Scientists found that since the age of 20 , the total weight of the bones to an annual rate of 1% decline, after the age of 50 , bone weight has been reduced by 30% overall - this is a scientific and startling conclusion .

As the " calcium hunger" , leading to the body's so-called "calcium move ." That is, the calcium bones constantly escape into the blood to maintain normal levels of serum calcium. The proportion between serum Carborundum Abrasives with calcium must maintain a long-term balance , otherwise , it will produce "calcium move " so abnormal calcium metabolism imbalance. A person within a few days or a month or calcium hunger temporarily affect serum calcium , but if things go on, calcium deficiency disease occurs : the child showed sparse hair , anorexia, irritability, night terrors , rickets , etc. ; youth skeletal dysplasia , eye disorders ; pregnant waist, leg pain , and affect fetal development , even teratogenic etc. ; osteoporosis in the elderly , degenerative bone hyperplasia , stone disease , hypertension , diabetes, dementia and so on.

Obviously, calcium plays an important role in the life course .

2013年12月14日星期六

Garnet sand Detail

garnet sand, garnet abrasive raw materials, with high hardness, high temperature stability, chemical resistance, uniform particles, high grinding efficiency, no scratches and other characteristics suitable for water jet cutting industry;. Various metals, plastics , wood and other surfaces sandblasted industry; ultra-fine grinding machinery industry, precision casting and for CRT glass, optical glass, silicon and other grinding industries;

Garnet sand origin

China garnet sand origin especially Inner Mongolia, Jiangsu Lianyungang, Rizhao most representative Mongolia garnet hardness, but mainly for the wind to wash the dust content is relatively large, the impact of cutting speed, the other, mostly small workshop production, deep Habitat inland transport costs are very high; Jiangsu Lianyungang garnet sand has been a major producer of domestic pomegranate sand, bright colors, hardness in general, open pit, mostly for local small workshop production, and therefore cheap low cost cheap, quality control is not strictly , often have a variety of impurities, often waterjet plug phenomenon, by the end of 2011, Lianyungang local government closed the mine, prohibit any person opened indiscriminate mining, which led to a very tight supply of garnet sand; Shandong Rizhao garnet sand for the deep mine, blackish dark red color, hardness, starting in 2011 in the domestic market, is less well known and therefore another origin, supply capacity, quality and stability, maritime land are more convenient, the next few years The main origin of Chinese garnet silica sand price.

Garnet sand process data and physicochemical properties

1, chemical analysis: (%)

SiO2 :36 - 40 AL2O3 :20 - 24 Fe2O3 :4 - 6 TiO2 :0-0 .5 MgO :8-13 FeO :22 - 24 CaO :6 - 9 MNO :0-0 .5

2, Hardness: Mohs 7.5-7.9;

3, specific gravity: 3.98

4, strength: Tough

5, gloss: shiny glass

6 forms: angular, irregular

7, crystal shape: isometric crystal system, octahedral corners

8 Streak: White

9 colors: cherry red, orange-red based

10, cleavage: Texture little, irregular cleavage plane

11 Transparency: Transparent

12, melting point: 1340 ℃

13: Magnetic: weak magnetic

14: Water Absorption: non-absorbent

15: Dispersion: Self-diffusion

16: Uniformity: homogeneous body

17, pathological response: None

18, the silicon content of hazardous freedom: None

Garnet sand origin

China garnet sand origin especially Inner Mongolia, Jiangsu Lianyungang, Rizhao most representative Mongolia garnet hardness, but mainly for the wind to wash the dust content is relatively large, the impact of cutting speed, the other, mostly small workshop production, deep Habitat inland transport costs are very high; Jiangsu Lianyungang garnet sand has been a major producer of domestic pomegranate sand, bright colors, hardness in general, open pit, mostly for local small workshop production, and therefore cheap low cost cheap, quality control is not strictly , often have a variety of impurities, often waterjet plug phenomenon, by the end of 2011, Lianyungang local government closed the mine, prohibit any person opened indiscriminate mining, which led to a very tight supply of garnet sand; Shandong Rizhao garnet sand for the deep mine, blackish dark red color, hardness, starting in 2011 in the domestic market, is less well known and therefore another origin, supply capacity, quality and stability, maritime land are more convenient, the next few years The main origin of Chinese garnet silica sand price.

Garnet sand process data and physicochemical properties

1, chemical analysis: (%)

SiO2 :36 - 40 AL2O3 :20 - 24 Fe2O3 :4 - 6 TiO2 :0-0 .5 MgO :8-13 FeO :22 - 24 CaO :6 - 9 MNO :0-0 .5

2, Hardness: Mohs 7.5-7.9;

3, specific gravity: 3.98

4, strength: Tough

5, gloss: shiny glass

6 forms: angular, irregular

7, crystal shape: isometric crystal system, octahedral corners

8 Streak: White

9 colors: cherry red, orange-red based

10, cleavage: Texture little, irregular cleavage plane

11 Transparency: Transparent

12, melting point: 1340 ℃

13: Magnetic: weak magnetic

14: Water Absorption: non-absorbent

15: Dispersion: Self-diffusion

16: Uniformity: homogeneous body

17, pathological response: None

18, the silicon content of hazardous freedom: None

The main purpose of the garnet and main component

The main purpose

(1) the steel structure, hull blast, Bridges, etc;

(2) metal, stone, glass, water knife cutting;

(3) the chemical, petroleum, pharmaceutical, water treatment filter medium;

(4) marble, optical lens, glass, leather and other materials of grinding;

(5) Brown Corundums wheel, oilstone, emery cloth and sand paper raw materials;

(6) the highway pavement, airport runway, prevent slippery, wear-resisting rubber paint, such as wear-resistant materials;

(7) is widely used in construction field, high-grade really stone paint exterior wall decoration interior decoration elegant temperament. The ideal new nonmetal wear-resisting flooring aggregate.

The main characteristics

The uvarovite highest value, but also the most rare

Main ingredients

Chemical composition: Al3Be2 [SiO4] 3

Crystallization characteristics: garnet belong to cubic system gem, the family on the crystal structure, belongs to the island silicate, common crystal morphology is rhombic dodecahedron, 38 sides and four corners shape, crystal visible grain growth.

Crystal system: belong to cubic system.

Refractive index: 1.74 to 1.90.

Hardness: 7-8.

Density: 3.5 to 4.3 grams per cubic centimeter.

Origin: Sri Lanka, India, Madagascar, the United States, China and other countries. More than a dozen provinces and autonomous regions in China are found to have gem grade garnet mineral.

Color: variety

Pyrope: red, purple, yellow and red

Almandine: brown, red, purple

Spessartine: yellow, orange, orange red

Grossular: brown yellow, yellow, yellow, green

Andradite: yellow, green, black

Uvarovite: green

(1) the steel structure, hull blast, Bridges, etc;

(2) metal, stone, glass, water knife cutting;

(3) the chemical, petroleum, pharmaceutical, water treatment filter medium;

(4) marble, optical lens, glass, leather and other materials of grinding;

(5) Brown Corundums wheel, oilstone, emery cloth and sand paper raw materials;

(6) the highway pavement, airport runway, prevent slippery, wear-resisting rubber paint, such as wear-resistant materials;

(7) is widely used in construction field, high-grade really stone paint exterior wall decoration interior decoration elegant temperament. The ideal new nonmetal wear-resisting flooring aggregate.

The main characteristics

The uvarovite highest value, but also the most rare

Main ingredients

Chemical composition: Al3Be2 [SiO4] 3

Crystallization characteristics: garnet belong to cubic system gem, the family on the crystal structure, belongs to the island silicate, common crystal morphology is rhombic dodecahedron, 38 sides and four corners shape, crystal visible grain growth.

Crystal system: belong to cubic system.

Refractive index: 1.74 to 1.90.

Hardness: 7-8.

Density: 3.5 to 4.3 grams per cubic centimeter.

Origin: Sri Lanka, India, Madagascar, the United States, China and other countries. More than a dozen provinces and autonomous regions in China are found to have gem grade garnet mineral.

Color: variety

Pyrope: red, purple, yellow and red

Almandine: brown, red, purple

Spessartine: yellow, orange, orange red

Grossular: brown yellow, yellow, yellow, green

Andradite: yellow, green, black

Uvarovite: green

The main types and main origin of garnet

The main kinds of

There are many types of purple tooth of the primary deposit, the main production in many magmatic or metamorphic rock class, most of the gem grade garnet supplier found in the alluvial placer. Purple tooth is the family of garnet mineral, is chemical complex silicate mineral silicate (island), usually with A3B2 [SiO4] 3 said. Among them A for Ca2 +, magnesium 2 +, Fe2 +, Mn2 + bivalent cation, such as Al3 + B said, Fe3 + and Cr3, + trivalent cations. Crystal is rhombic dodecahedron, four corners 38 sides, or the combination of both. Aggregate for granular or massive. Garnet color affected by the composition, present a variety of colors, including red series including red 'pink' purple 'orange; Yellow series including yellow 'orange' densely yellow brown yellow; Green series including green olive green. Crystal glass luster, the adamantine luster, fracture oily luster. Transparent to translucent. Not homogenate, pleochroism, no double refraction phenomenon. Garnet can be divided into two series, six main varieties: almandine series (pyrope, almandine and spessartine) and andradite series (uvarovite, grossular andradite).

The main producing area

garnet suppliers origin in China especially in Inner Mongolia, lianyungang, jiangsu, shandong rizhao most representative. Garnet sand hardness of Inner Mongolia, but mainly for the wind, dust content is bigger, affect the cutting speed. In addition, as small workshops to produce more, deep in the inland, transport costs are very high; Jiangsu lianyungang garnet sand has been the leading producer of domestic garnet sand, bright color, hardness, general open pit mine, for the local small workshops to produce more, so low cost low price cheap, quality control is not strict, there are often various impurities, often have the phenomenon of water knife plug. At the end of 2011, the government closed the local mines, lianyungang forbid anyone to disorderly open excessive mining, lead to domestic garnet sand supply very nervous; Shandong rizhao garnet for deep mines, color slants deep black, high hardness, since 2011 sales in the domestic market, so it is less known another origin, large output, stable quality, sea land transportation is convenient, is the leading producer of the next few years China garnet.

There are many types of purple tooth of the primary deposit, the main production in many magmatic or metamorphic rock class, most of the gem grade garnet supplier found in the alluvial placer. Purple tooth is the family of garnet mineral, is chemical complex silicate mineral silicate (island), usually with A3B2 [SiO4] 3 said. Among them A for Ca2 +, magnesium 2 +, Fe2 +, Mn2 + bivalent cation, such as Al3 + B said, Fe3 + and Cr3, + trivalent cations. Crystal is rhombic dodecahedron, four corners 38 sides, or the combination of both. Aggregate for granular or massive. Garnet color affected by the composition, present a variety of colors, including red series including red 'pink' purple 'orange; Yellow series including yellow 'orange' densely yellow brown yellow; Green series including green olive green. Crystal glass luster, the adamantine luster, fracture oily luster. Transparent to translucent. Not homogenate, pleochroism, no double refraction phenomenon. Garnet can be divided into two series, six main varieties: almandine series (pyrope, almandine and spessartine) and andradite series (uvarovite, grossular andradite).

The main producing area

garnet suppliers origin in China especially in Inner Mongolia, lianyungang, jiangsu, shandong rizhao most representative. Garnet sand hardness of Inner Mongolia, but mainly for the wind, dust content is bigger, affect the cutting speed. In addition, as small workshops to produce more, deep in the inland, transport costs are very high; Jiangsu lianyungang garnet sand has been the leading producer of domestic garnet sand, bright color, hardness, general open pit mine, for the local small workshops to produce more, so low cost low price cheap, quality control is not strict, there are often various impurities, often have the phenomenon of water knife plug. At the end of 2011, the government closed the local mines, lianyungang forbid anyone to disorderly open excessive mining, lead to domestic garnet sand supply very nervous; Shandong rizhao garnet for deep mines, color slants deep black, high hardness, since 2011 sales in the domestic market, so it is less known another origin, large output, stable quality, sea land transportation is convenient, is the leading producer of the next few years China garnet.

2013年12月13日星期五

The introduction of garnet

garnet is a kind of mineral, garnet crystals with pomegranate seeds is similar to the shape, color, so the name "garnet. Good color, transparent Garnet can become gem, English name for use Garnet Garnet, "Granatum" evolved from Latin, meaning "as a seed. Common garnet red, but the variety of its color is very wide, enough to cover the whole spectrum of colors. Common garnet because of its chemical composition and identified as six, respectively red garnet (Pyrope), iron and aluminum garnet (Almandine), manganese aluminum garnet (Spessartite), the calcium iron garnet, Grossular Andradite () (Grossular) and the Uvarovite (Uvarovite).

Garnet, also called garnet. As the floorboard of the family of a mineral, the English use Garnet, Granatum, Latin origin means "granular, like seeds". According to the English transliteration, domestic minority people also call it the "stone".

Chinese name garnet, vividly portrayed the appearance characteristics, the mineral from the shape to the color as "seed" in the pomegranate. According to legend, the pomegranate from rest, ever said "rest in peace in central", hereinafter referred to as "pomegranate" of interest, and the sound of "pomegranate".

China's jewelry industry, the technology of the garnet "purple tooth wu". "Tooth uri (gu)," derived from Arabic Yakut (ruby), and because of garnet is purple, so named purple teeth.

For thousands of years, garnet is regarded as a symbol of faith, firmness and simplicity. People want to own, and worship it, not only because of its aesthetic value adornment, more important is gems were believed to have an incredible magic power, make the person not jeopardized, killed ChengXiang, can keep honor status forever, and has important function of memorial.

Today, January birthstone, garnet, as a symbol of the faithful, love and virtue.

Garnet with similar distinction gems, synthetic garnet. Similar to a variety of garnets color stones including ruby, sapphire, synthetic corundum, topaz and emerald, jade stone, etc., are heterogeneous body, can distinguish under polariscope. In density, inclusions, refractive index, dispersion degree, fluorescence, etc can be differentiated. The difference between the garnet and synthetic green garnet mainly depends on internal inclusions and density. Synthesis of green gadolinium gallium garnet, yttrium aluminum garnet, color uniformity, the absence of any defect, I see a small amount of air bubbles, red filter. Density: gadolinium gallium garnet 7.05 g/cm3, gadolinium gallium garnet 4.58 grams/cubic centimeter, are much higher than the natural garnet. In addition, the refractive index, dispersion, and each has its own characteristics, can make the difference.

Green garnet can strengthen its vitality and charm, to improve the problem of department of gynaecology; Contribute to the regeneration of the body, to accelerate the wound healing; Can eliminate worries and depression, make popular feeling affection cheerful; Green energy is lucky, wearing a green garnet can improve their own luck. Red garnet, very suitable for weak physique, qi and blood is not the women, can add three rounds of the energy, improve the inner loop and the disease of department of gynaecology.

Garnet, also called garnet. As the floorboard of the family of a mineral, the English use Garnet, Granatum, Latin origin means "granular, like seeds". According to the English transliteration, domestic minority people also call it the "stone".

Chinese name garnet, vividly portrayed the appearance characteristics, the mineral from the shape to the color as "seed" in the pomegranate. According to legend, the pomegranate from rest, ever said "rest in peace in central", hereinafter referred to as "pomegranate" of interest, and the sound of "pomegranate".

China's jewelry industry, the technology of the garnet "purple tooth wu". "Tooth uri (gu)," derived from Arabic Yakut (ruby), and because of garnet is purple, so named purple teeth.

For thousands of years, garnet is regarded as a symbol of faith, firmness and simplicity. People want to own, and worship it, not only because of its aesthetic value adornment, more important is gems were believed to have an incredible magic power, make the person not jeopardized, killed ChengXiang, can keep honor status forever, and has important function of memorial.

Today, January birthstone, garnet, as a symbol of the faithful, love and virtue.

Garnet with similar distinction gems, synthetic garnet. Similar to a variety of garnets color stones including ruby, sapphire, synthetic corundum, topaz and emerald, jade stone, etc., are heterogeneous body, can distinguish under polariscope. In density, inclusions, refractive index, dispersion degree, fluorescence, etc can be differentiated. The difference between the garnet and synthetic green garnet mainly depends on internal inclusions and density. Synthesis of green gadolinium gallium garnet, yttrium aluminum garnet, color uniformity, the absence of any defect, I see a small amount of air bubbles, red filter. Density: gadolinium gallium garnet 7.05 g/cm3, gadolinium gallium garnet 4.58 grams/cubic centimeter, are much higher than the natural garnet. In addition, the refractive index, dispersion, and each has its own characteristics, can make the difference.

Green garnet can strengthen its vitality and charm, to improve the problem of department of gynaecology; Contribute to the regeneration of the body, to accelerate the wound healing; Can eliminate worries and depression, make popular feeling affection cheerful; Green energy is lucky, wearing a green garnet can improve their own luck. Red garnet, very suitable for weak physique, qi and blood is not the women, can add three rounds of the energy, improve the inner loop and the disease of department of gynaecology.

2013年11月15日星期五

Silicon!!!!!

silicon

Crystalline black silicon carbideis dark blue, very crisp, is a typical semiconductor.Chemical properties are very stable.At room temperature, to eliminate hf,Outside, it is difficult to react with other substances.

The purpose of the silicon:(1) of high purity silicon is important semiconductor materials.In the first IIIA monocrystalline silicon containing trace elements, the formation of p-type silicon semiconductor;With traces of the first VA group elements, formation of n-type and p-type semiconductors together, can make the solar cell, transform radiant energy

Into electrical energy.In the development of energy is a kind of promising material.

(2) metal ceramic, important material of space travel.Mix of ceramic and metal sintering, made from metal ceramic composite materials, it is high temperature resistant

, rich toughness, can cut, both inherited the respective advantages of metal and ceramic, and compensate for birth defects of the two.Can be applied to

Military weapons made the first space shuttle "Columbia" through dense atmosphere can resist high speed friction produced by high temperature, full

To rely on it that thirty-one thousand pieces of silicon watts spells build by laying bricks or stones into the shell.

(3) optical fiber communication, the latest modern methods of communication.With pure silica control the transparency of glass fibers, laser on the glass

Fibre channel, total reflection forward transmission, the countless times to replace the heavy cable.Optical fiber communication capacity is high, that a human hair

Thin glass fiber, 256 phone, can transmit at the same time it also without electricity, magnetic interference, not afraid of hacking, has a high degree of confidentiality

.Optical fiber communication will make the 21st century, the human life has a revolutionary change.

(4) performance of organic Black silicon carbidecompounds.For example, organic silicon plastic is an excellent waterproof coating material.The walls in the underground railroad spraying organic

Silicon, can solve the water seepage problems.In the ancient cultural relics, sculpture, appearance, apply a thin layer of silicone plastic, can prevent

Moss breeding, resist the wind rain and weathering.The monument to the people's heroes in tiananmen square, is through organic silicon plastic processing

Surface, so white, pure and fresh forever.

What industry with silicon powder usage biggest ~!

The prospect of Silicon carbidepowder industry later?

We look at from the following several aspects: the international market space, the world demand for silicon powder 100000 tons.day

This is the largest country in the production of epoxy powder coating material production in the world, the demand for silicon powder 30000 tons, all rely on imports.The annual demand

Silicon powder 20000 tons;South Korea's demand for silicon powder 10000 tons.Domestically, according to concerning sectional statistic, high purity 300 mesh, 1000 mesh

Micro silicon powder and ultrafine crystalline silicon powder consumption at home and abroad every year in 20% - 35% of the increase, with the enlargement of the range of application

Volume growth will continue to increase.Molten class of 2001, China's total consumption of 18000 tons, 12000 tons of imports, in 2004 total amount 78000

Tons, with imports of 48000 tons, the total amount of this year is expected to exceed 100000 tons, has imported 25000 tons in the first half of the year.Silicon micro technology field

Annual demand for 20000 tons of powder. it is presumed that the domestic demand for type molten silicon powder, 15, 2010-2010

Tons;In terms of electronic products, the demand for crystalline silicon powder, the annual demand is expected to exceed 700000 tons;In the fused silica ceramics

Surface, the domestic demand for black silicon carbidepowder in will reach 30000 tons, the wide prospect of market.It is understood that the silicon powder mainly in high-end products

Rely on imports.With China's accession to the WTO market, as well as the rapid development of China's IT industry, electronic packaging in the industry will gradually move to

Countries.Experts predicted: the new century China will become the world's superpower encapsulation, high-purity ultrafine silica powder and other downstream products market will be over

The expanded.Is profit space, though with silicon powder products, but the price is a far far, such as ordinary silicon powder is only 600 yuan / 300 courses

8000-8000 tons. And ultrafine high-purity electronics for micro powder price is as high as 100000 yuan/ton, if you upgrade to nanoscale

Molten micro powder tons price is higher more than 200000 yuan/ton.Product upward development space in our country the relevant units and successfully developed electronic levelHigh-purity ultrafine silica powder.This is a market attractive electronic materials products.High-purity ultrafine silica powder is large-scale integrated electricity subgrade

Board and electronic packaging materials of the main raw material, it combined with epoxy resin to complete chip or adhesive sealing components.Ultrafine silica powder

In the epoxy resin mixed ratio determines the thermal expansion coefficient of the substrate.The higher the proportion of silicon powder, thermal expansion coefficient of the substrate

Small, that is, the closer it gets to the thermal expansion coefficient of silicon wafer, which can avoid uneven expansion caused by damage to the micro line.Therefore, the silicon

The purity of powder, fineness and particle size distribution have strict requirements.Enterprise instance above analysis it can be seen that the silicon powder has the attractive

Market prospect and wide development space.With the development of new and high technology, more and more high to the requirement of micro silicon powder materials, the enterprise can be completely

Based on the needs of the market, less investment, adjust product structure, develop the deep processing products, in order to improve the competitiveness of the enterprises

But these should have a necessary premise - science and technology innovation.Only rely on science and technology to develop high-tech products, to make empty market

Between the development and form a virtuous circle.

2013年11月11日星期一

Green silicon carbide is what, how is it made of

Green silicon carbide is a petroleum coke and the high quality silica as the main raw material, adding salt as additive, via high temperature electric resistance furnace smelting.Its hardness is between fused alumina and diamond, mechanical strength is higher than fused alumina.

2013年11月8日星期五

Silicon carbide purpose

Black silicon carbide semiconductor can handle "extreme environment", it is alleged that silicon carbide wafer can withstand even Venus or near the sun's heat. Previous studies show that even at a temperature of 560 degrees Celsius, silicon carbide wafer in the absence of cooling device is still functioning normally. calcium siliconwafer has wide applied prospects in the field of communication, can let the high-definition TV transmitters provide a clearer signal and image; Also can be used in jet and automobile engine, monitoring the motor running. At the same time, it also can be used in the field of space exploration, help nuclear-powered spacecraft perform more complex tasks. French physicist predicted that in the field of chip manufacturing silicon carbide replace silicon has been far too.

2013年9月28日星期六

How to identify black silicon carbide

Black silicon carbide as chemical stability, high thermal conductivity , thermal expansion coefficient, good wear resistance , except for the abrasive used , there are many other uses , for example: a special process the silicon carbide powder coating on the turbine impeller or cylinder block the wall, can improve the wear resistance and extended service life 1 to 2 times ; made ??of high-grade refractory to , thermal shock resistance , small size, light in weight , high strength, good energy saving effect .

How do black silicon carbide identification:

1 Appearance Density : And you want to see the density of silicon carbide , silicon carbide and high chamber generally loose content is higher than the number ;

(2) Test Hardness: It 's more than the glass hard , can use when glass cutter ;

3 see color: from the color , the difference with green silicon ;

4 experiment : to find a glass container , put the pieces into a certain amount of silicon carbide , add water , shake , look at its turbidity , water darker , indicating its higher carbon , silicon carbide, but less ; the water drained , look silicon carbide in the quartz sand how many unfired raw numbers , then make a preliminary judgment, if you engage in over- testing, your judgment will not be up and down the error 3 .

How do black silicon carbide identification:

1 Appearance Density : And you want to see the density of silicon carbide , silicon carbide and high chamber generally loose content is higher than the number ;

(2) Test Hardness: It 's more than the glass hard , can use when glass cutter ;

3 see color: from the color , the difference with green silicon ;

4 experiment : to find a glass container , put the pieces into a certain amount of silicon carbide , add water , shake , look at its turbidity , water darker , indicating its higher carbon , silicon carbide, but less ; the water drained , look silicon carbide in the quartz sand how many unfired raw numbers , then make a preliminary judgment, if you engage in over- testing, your judgment will not be up and down the error 3 .

2013年9月26日星期四

Green silicon carbide powder magnetic separation is very important

Green silicon carbide is a high temperature high-tech products , its color is green, crystal structure is shaped products, microscopic shape of a hexagonal crystal , silicon carbide Mohs hardness of 9.2 , a Vickers hardness of 3000 - 3300 kg / mm 2, the Knoop hardness of 2670-2815 kg / mm , hardness of 3300 kg per cubic millimeter.

Green silicon carbide material to be crushed by magnetic separation . Green silicon carbide powder is very important that such general magnetic material after the wet- milled into a concentration of 25 % to 40 % of the slurry for wet magnetic separation to remove iron into the milling time , the production scale is small , can be permanent block wet magnetic separation . The aircraft magnetic field strength of 7000 Oe or more , stopping every 20 ~ 30min filters cleaned once removed , can make the material magnetic material content to 0.002% or more, when the large-scale production , can be wet magnetic separator as CST162 electromagnetic iron machine . Green silicon carbide powder Scope: do bonded and coated abrasives , and polishing , machining cast iron , tungsten carbide, titanium, high-speed steel , etc., can grind glass, ceramics, stone , agate and jade fine jewelry other non-metallic materials, heating elements and thermal elements , such as : Carbide , optical glass, glass and ceramics and other hard and brittle ma non-metallic materials , can also be used to manufacture high-grade refractory , electric components and electrical component products.

Green silicon carbide material to be crushed by magnetic separation . Green silicon carbide powder is very important that such general magnetic material after the wet- milled into a concentration of 25 % to 40 % of the slurry for wet magnetic separation to remove iron into the milling time , the production scale is small , can be permanent block wet magnetic separation . The aircraft magnetic field strength of 7000 Oe or more , stopping every 20 ~ 30min filters cleaned once removed , can make the material magnetic material content to 0.002% or more, when the large-scale production , can be wet magnetic separator as CST162 electromagnetic iron machine . Green silicon carbide powder Scope: do bonded and coated abrasives , and polishing , machining cast iron , tungsten carbide, titanium, high-speed steel , etc., can grind glass, ceramics, stone , agate and jade fine jewelry other non-metallic materials, heating elements and thermal elements , such as : Carbide , optical glass, glass and ceramics and other hard and brittle ma non-metallic materials , can also be used to manufacture high-grade refractory , electric components and electrical component products.

2013年9月22日星期日

About emery introduce the main functions

Emery Because high temperature, corrosion resistance, high strength and other properties, it poured with steel sliding gate, smelting rare metals, special alloys, ceramics, blast furnace lining (walls and tubes); chemical containers, spark plugs, anti- Thermal oxidation resistant coating.

Because of hardness, wear resistance, high strength characteristics, in the chemical system, used to do all kinds of repercussions vessels and pipelines, chemical pump parts; make machine parts, all kinds of mold, such as wire drawing dies, extrusion die nozzle pencil etc.; make tools, dies abrasives, bulletproof material, human articular, seal mold ring.

industry, refractory material industry of choice material. Emery important for ceramic abrasive, high abrasive, organic abrasive, abrasive belt, coated abrasives, etc., credentials residual carbon content is divided into: calcined corundum C ≤ 0.05%, carbon corundum C ≤ 0.10% , ordinary corundum C ≤ 0.15%.

Because of hardness, wear resistance, high strength characteristics, in the chemical system, used to do all kinds of repercussions vessels and pipelines, chemical pump parts; make machine parts, all kinds of mold, such as wire drawing dies, extrusion die nozzle pencil etc.; make tools, dies abrasives, bulletproof material, human articular, seal mold ring.

brown fused

aluminium oxide insulating material, such as lightweight corundum bricks, corundum hollow spheres and fiber products, used in various high-temperature furnaces throughout the furnace wall and roof, both high temperature insulation. Size sand corundum corundum block by artificial selection, admission on the roll, ball mill, and other settings Barmac deployment processing equipment, particle size by the F8-F325. Important for polishing, grinding, industrial grinding, etc., you can also press customer requirements at washing, pickling disposal punishment essentials processing, the difference can probably satisfied customers demand.

Britain at the end of low-carbon corundum furnace and special process and then dispose of punishment, corundum low carbon content in the waste, so that the product is not in use powder, not burst, toughness is the Carborundum

Abrasivesindustry, refractory material industry of choice material. Emery important for ceramic abrasive, high abrasive, organic abrasive, abrasive belt, coated abrasives, etc., credentials residual carbon content is divided into: calcined corundum C ≤ 0.05%, carbon corundum C ≤ 0.10% , ordinary corundum C ≤ 0.15%.

2013年9月18日星期三

Explains how to better develop the corundum

Corundum is the most common major abrasive a product, the product has many advantages, abrasives carried out related to the conduct. Current national exercise restraint corundum, screening exercise small stove, but in fact is encouraging enterprises to take a group of road.

Known as dental abrasives industry reputation. Commonly used in the grinding or abrasive abrasive grinding thing as the parts to be processed to be machined, and reaches a certain skill requirements. Twelfth Five-Year Plan "beginning to carry out abrasive professional conduct has brought great opportunities and challenges. Energy conservation, hygiene production will showcase the produce in abrasive occupational category, in addition, the state machinery , shipbuilding, automobiles, airplanes and other areas of policy will also abrasive corundum abrasives production and carry out a great impact.

As a special abrasive incomparable career, there is abrasive in terms of energy saving exercise problems, current domestic overcapacity corundum appearance, followed by the implementation of national energy conservation policy, the next step will be a screening approach point behind corundum occupations capacity. Estimates of future five-year career abrasives tone will also be carried out throughout the country's economic policy tone.

Our abrasive mall after nearly a decade of conduct, constitutes a fundamental mall format once. China has become abrasive producing countries, but not power. As a special abrasive incomparable career, there is abrasive in terms of energy saving exercise problems, current domestic overcapacity corundum appearance, followed by the implementation of national energy conservation policy, on small corundum processing Square To filter on brown corundum continue to carry out, to embark on the Group of the road.

Known as dental abrasives industry reputation. Commonly used in the grinding or abrasive abrasive grinding thing as the parts to be processed to be machined, and reaches a certain skill requirements. Twelfth Five-Year Plan "beginning to carry out abrasive professional conduct has brought great opportunities and challenges. Energy conservation, hygiene production will showcase the produce in abrasive occupational category, in addition, the state machinery , shipbuilding, automobiles, airplanes and other areas of policy will also abrasive corundum abrasives production and carry out a great impact.

As a special abrasive incomparable career, there is abrasive in terms of energy saving exercise problems, current domestic overcapacity corundum appearance, followed by the implementation of national energy conservation policy, the next step will be a screening approach point behind corundum occupations capacity. Estimates of future five-year career abrasives tone will also be carried out throughout the country's economic policy tone.

Our abrasive mall after nearly a decade of conduct, constitutes a fundamental mall format once. China has become abrasive producing countries, but not power. As a special abrasive incomparable career, there is abrasive in terms of energy saving exercise problems, current domestic overcapacity corundum appearance, followed by the implementation of national energy conservation policy, on small corundum processing Square To filter on brown corundum continue to carry out, to embark on the Group of the road.

2013年9月16日星期一

Black silicon carbide simple way to identify what

In fact, distinguish black silicon

carbide method is very simple,

generally can tell from the color on the out, but some are dyed , and

this time we should better understanding and from the other side to

compare .

Black silicon carbide simple identification method :

Color difference compared with green silicon ; hardness, it is much harder than glass , can be used when the glass cutter ; find a glass container , put the pieces into a certain amount of silicon carbide , add water , shake , look at its turbidity , AGUA black , indicating its higher carbon , silicon carbide abrasive , but less ; the water drained , watching the black silicon carbide in the quartz sand how many unfired raw numbers , and thus make a preliminary judgment, if you engage in over- testing , your judgment will not be up and down the error 3 . There you look at the density of silicon carbide , silicon carbide and high chamber generally loose content is higher than the number .

Black silicon carbide simple identification method :

Color difference compared with green silicon ; hardness, it is much harder than glass , can be used when the glass cutter ; find a glass container , put the pieces into a certain amount of silicon carbide , add water , shake , look at its turbidity , AGUA black , indicating its higher carbon , silicon carbide abrasive , but less ; the water drained , watching the black silicon carbide in the quartz sand how many unfired raw numbers , and thus make a preliminary judgment, if you engage in over- testing , your judgment will not be up and down the error 3 . There you look at the density of silicon carbide , silicon carbide and high chamber generally loose content is higher than the number .

2013年9月13日星期五

There are new developments in silicon carbide carbon double success

Technology is evolving , is endless , master of science and technology to master the future , the current silicon carbide in science and technology , there has been a new development , the standard of silicon carbide prospects bright.